We know that sometimes zone controls can be a headache. Complicated controls and low quality dampers can make a zoning job more trouble than it’s worth. Not with SmartZone controls and Ecojay dampers. Simple controls and heavy-duty dampers take the hassle out of zoning.

Why a temperature sensor is so important with Zoning

SupportCommentEquipment Protection

Protecting the equipment from running too hot or too cold is very important consideration when selecting zoning panel. By the nature of zoning, airflows in the duct work are being adjusted as zones open and close. Even in Pressure Relief is adequately designed using a bypass or other method, temperatures across the coil and the furnace can fluctuate. An example is on a mild 60 degree day, a single small zone calls for heat. In this case, a large percentage of already “heated” air is being re-circulated or forced back through the furnace to be “re-heated.” This condition can cause temperatures that will cause the fail-safe temperature sensor to trip on the equipment. The same thing can happen in the cooling mode with consequences that look like frozen coils and potentially damaged compressors.

The need for protection has OFTEN been overlooked with zoning and has caused many failures that have been generically blamed on “zoning.” Much of the negative feelings about zoning has been caused by this problem. The solution is available on most modern panels: A supply air temperature sensor (discharge air) that allows the zoning panel to cut off the equipment when the temperature is too high or too low.

Staging

The zoning panel used here is determined by the equipment being used on the application. If the equipment is single stage, any zoning panel available should work that meets the other guidelines described here. When multiple stages are being used, there are many less options. First of all, many inexpensive zoning panels do not control more than one stage (although most of these don’t meet other criteria described in this book either). Secondly, and often overlooked is the staging control method. Many available boards simply control second or third stage based on time alone. In other words… if stage one is on for 8 minutes, turn on stage two. More accurately, some panels include a 2nd stage lockout if only one zone is calling. Best of all, some panels available use a supply temperature sensor to stage based on both time and temperature. With a temp sensor controlling stating the most efficient use of equipment can be made, not to mention the protection from freeze or overheating it provides.

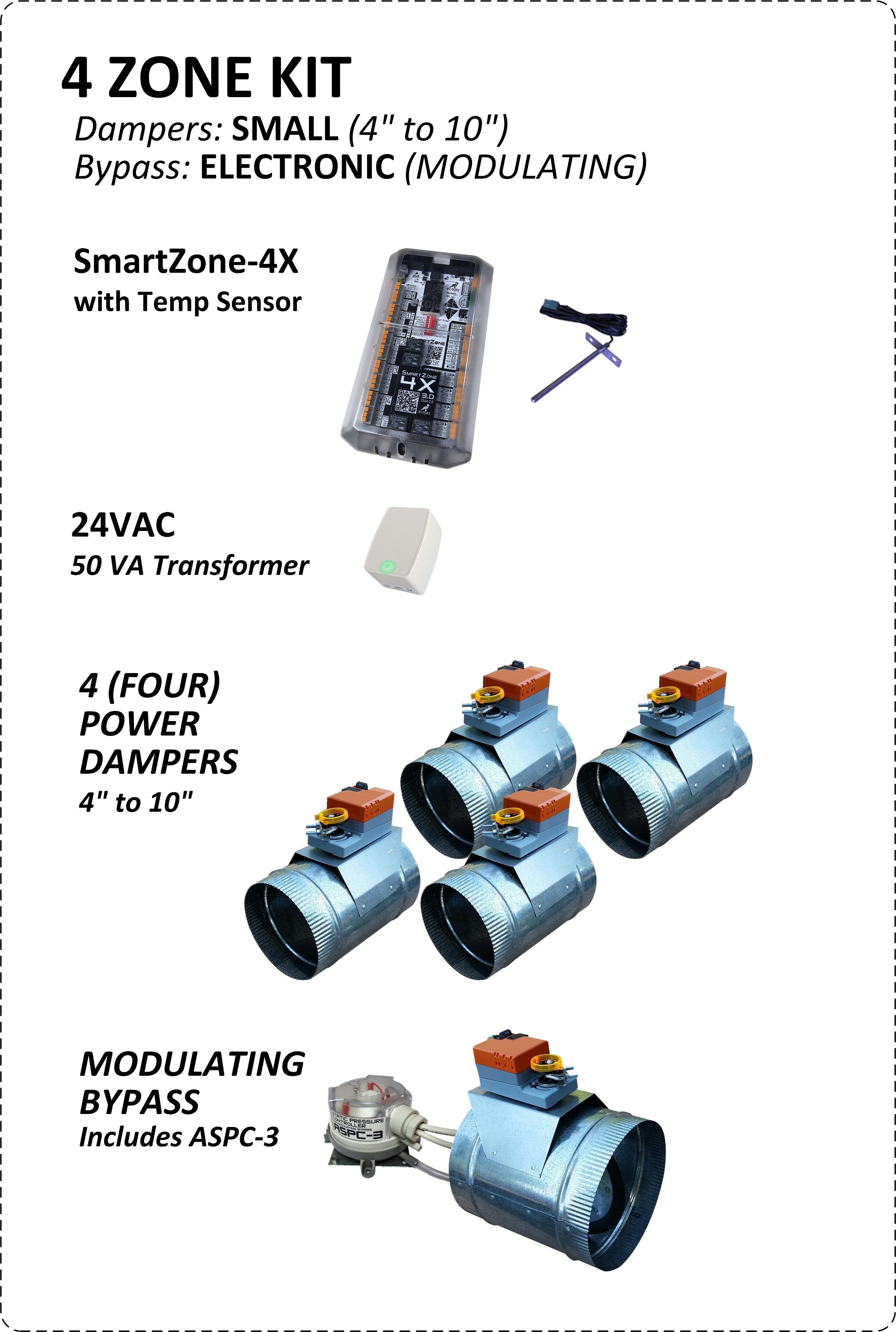

SmartZone Static Pressure Control for Modulating Bypass

SupportCommentWhy SmartZone Static Pressure Control so much better? It's pre-wired, saving lots of time and hassle.

Much better than the competition... more accurate and the easiest by far to install. The video below shows that a typical static pressure control takes more than 4X as long to install when compared to the same ECOJAY SmartZone Static Pressure Control (ASPC)

Zoning Transformer Size & Fuse Protection

CommentTransformer Sizing

Sizing the transformer for a zoning system is often overlooked because of the trivial nature of the role it plays in the zoning application. It is, however, critical to provide a properly sized transformer on any Zoning system. Zoning panels can misbehave and even cause the equipment to do some erratic things if the transformer has been undersized. Over sizing is not typically an issue, so this should be re-named MINIMUM Transformer Sizing.

NOTE: Included Transformer - Don’t be deceived by a zoning system that has an included transformer, this doesn’t mean you do not have to calculate the necessary transformer size. The included transformer may not be enough to handle all of the dampers or the type of thermostats that the specific application demands.

Calculation

[Zoning Panel VA]+[All Thermostats VA]+ [All Dampers VA]=Total VA<Transformer Size

The Transformer Size must be GREATER than the Total VA. Simple, right? Yes, it is simple, but crucial to calculate accurately. So, take into consideration ALL of the pieces being attached to the zoning panel. Refer to the manufacturer for exact VA ratings on each of the pieces.

- Dampers - 2 to 12 VA (each Damper)

- Thermostats - 1 to 3 VA (each Thermostat)

- Zone Panel - 10 to 20 VA

See SmartZone Guide for VA ratings

Fuse Size

In all zoning applications the transformer secondary (24VAC) side should be fused with a standard in-line fuse. This is very important with zoning because the zoning panels can be sophisticated electronics that need protection from the vulnerabilities in the field.

Some transformers have breakers on board but it is still recommended to provide a field installed in-line fuse to protect the zone panel. The resettable breaker built on some transformers is sized to only trip if the voltage exceeds the maximum of the transformer. The inline fuse, on the other hand, can be sized according to the specific installation.

The inline fuse size is calculated by using the TOTAL VA requirement for the system (in the transformer sizing calculation section). This number is divided by 20 to get the FUSE SIZE in amps. The 20 comes from 24VAC X power factor (assuming a power factor of 0.83).

FUSE SIZE (AMPS) = (Total VA)/(24V*0.8333) = (Total VA)/20

This means a 40 VA transformer should never have more than a 2 AMP fuse on the secondary side.

NOTE: Wall plug transfomers typically have a built in fuse that is sufficient but it wouldn't hurt to put an inline fuse even with this style of transformer.

Light switches don’t save energy… turning the light switch OFF saves energy

Zone Control InfoCommentZoning Return on Investment – Payback?

There is no short answer to this question with Zone Control. Energy CAN be saved with zoning but it is also capable of increasing the comfort of a home. Because of this, a zoning system can both save and cost energy depending on how the homeowner uses it. User habits of operating the system primarily determine how much energy will be used or saved.

What type of damper is best Spring or Power?

SupportCommentDamper Type Selection

There are two basic types of dampers available in mass today. Although, there are other damper types such a “balloon” type and pneumatic controlled dampers (used more commonly on DDC systems not included), for this context we will discuss these two main types of dampers:

- Spring Open or Close (Spring Damper)

Power Open & Power Close (Power Damper)

Power Dampers

Power Open /Power Close dampers use three wires to either power open or power close. They zone panel is responsible for supplying a 24VAC signal to either the PO (Power Open) or PC (Power Closed) terminal of these dampers. This type of damper was traditionally reserved for “higher-end” or commercial applications because of the cost. In recent years, however, motor prices have decreased and power dampers have become much more affordable (often no more expensive than the spring equivalent especially when labor and reliability are factored in.) Primary advantages of Power Dampers include lower power consumption, quiet operation and more reliable parts. Given the choice, Power Dampers, are almost always preferable. The only exception to this is when code requires Spring Dampers.

Spring Dampers

The way Spring Dampers work is they have a motor that, when energized by the zoning panel, it closes the damper. When the damper is ready to open, the motor stops powering the damper closed and a spring opens the damper blade back up. Spring Dampers have been used in an “economy” application for many years. The two primary advantages of a Spring Damper are: 1. If the system loses power they “fail” open… but if the system loses power, the equipment isn’t going to be running either and therefore will not matter in MOST cases. 2. They only require two wires for operation. One of the negative arguments against Spring Dampers has historically been reliability. This mostly a result of one of its benefits… the cost. The inherent lifecycle of any spring actuated mechanism (even if it is in the millions) is less reliable than a system that doesn’t include this potential failure point. In addition to this, the motor that is used has to be a very specific model that allows for running backwards without damage yet still has to be powerful enough to overcome the spring trying to pull the blade in the opposite direction. This leads to probably the BIGGEST downfall of using a Spring Damper - the power consumption. Most Spring Dampers on the market use 3 to 4 times the power of the equivalent Power Damper (10-12 VA vs. 2-3VA). This could be the difference in using a standard sized transformer and having to go to a very large (and expensive) over-sized transformer. In summary: spring dampers are NOT recommended unless absolutely necessary for some reason.

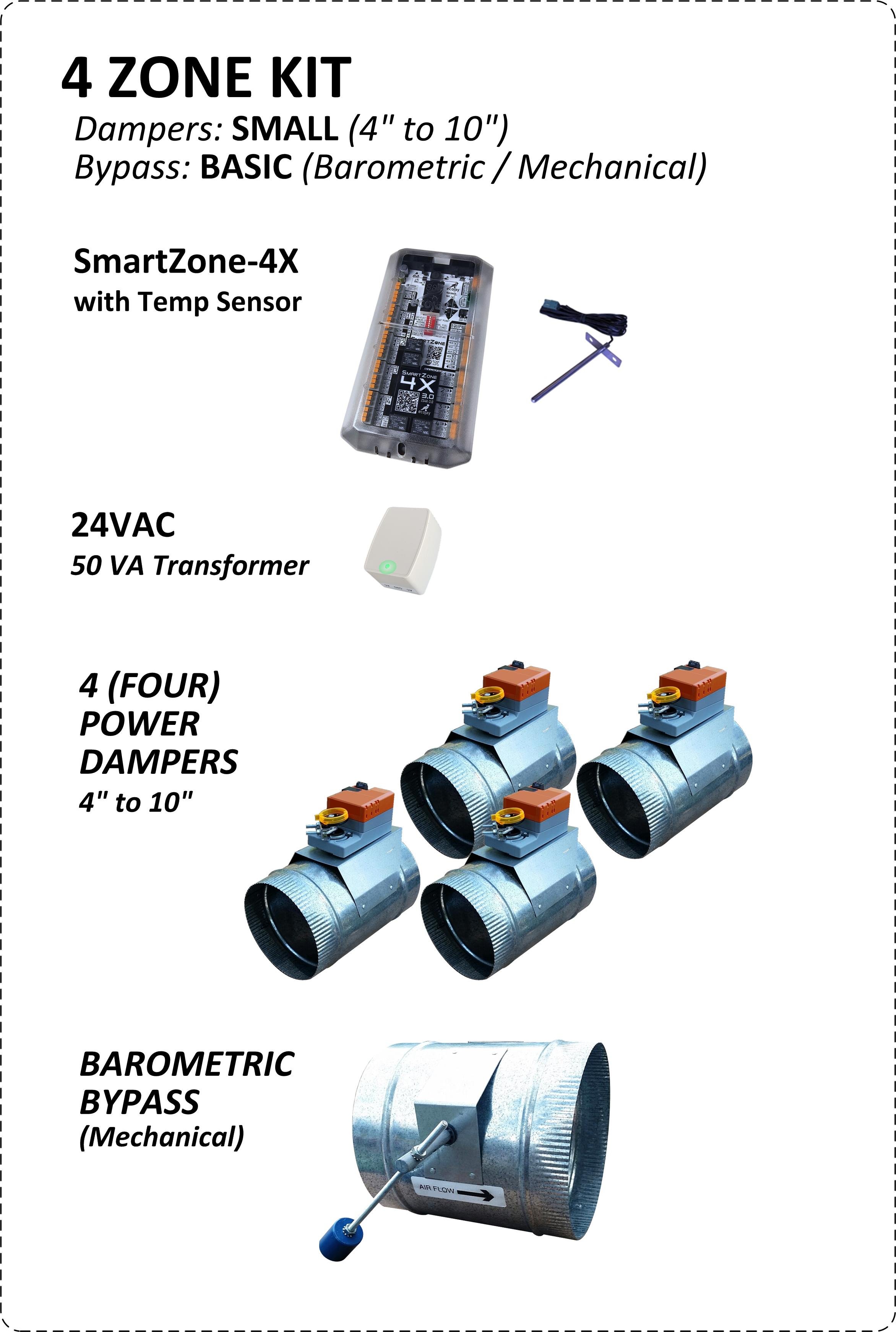

The parts that make an HVAC Zoning System

SupportCommentElements of Zoning

A Zoning System consists of 4 primary pieces:

Thermostats

Zoning Control Panel

Dampers

Equipment

1. Thermostats

Thermostats are used in just the same way that a typical thermostat is used except with a zoning system there is ONE thermostat located in each area or “zone.” Instead of connecting these thermostats to the equipment like a typical application, with zoning all the thermostats are connected to the Zoning Panel. Suggest purchasing on Amazon.com or from wherever 24VAC thermostats are sold.

2. Zoning Control Panel

The Zoning Panel is the “brains” of the operation. This computer-like electronic board, reads the calls from all the thermostats and makes decisions about what to energize on the equipment (heat, cool or fan) AND which dampers to open or close. Zoning Control Panels come in MANY shapes, sizes, and colors but with SmartZone you are just selecting the number of zones)

3. Dampers

Not only are the thermostats connected to the Zoning Panel but so are the dampers. A damper is to airflow in the duct like a faucet is to water in a pipe. In other words, the damper acts like a valve in the duct system to divert air to the zones where it is needed.

4. Equipment

Finally, the Equipment is also connected to the Zoning Panel. The equipment refers to the heating and cooling (HVAC) unit. This can come in many shapes, sizes, and configurations. In order to apply zoning to any equipment, the correct zoning Panel mush be chosen. Some Zone Panels are very specific and can only be used with certain types of equipment while some are much more versatile and can be used on almost ANY type of equipment used.

The above four parts make up the pieces of a Zoning System, but since in a standard system you already have two of these parts (THERMOSTAT and EQUIPMENT). The addition of a zoning system really consists of adding only two different parts, a ZONING PANEL and DAMPERS. This makes zoning one of the easiest and affordable ways to gain the much desired improvement of comfort and efficiency. With these parts installed properly a user can enjoy the ability for both added comfort and increased energy savings.

What size dampers do I need?

Support1 CommentDamper Size Selection

Typically in an existing install, the duct size will determine the damper sizes needed. But if starting with a new duct system 2 variables must be known to determine damper sizes.

Total CFM of System

Calculate using the “whole house load” with maximum diversity.

- Zone CMF (needed for each Zone)

Total the rooms associated with each zone separately to get the “Zone CFM” (No diversity)

Round Damper Sizes

Round damper sizes range from 4” to 18” typically in 1” increments up to 10” and in 2” increments up to 18”. There are two numbers that must be used when designing a zoning system with regard to all dampers.

Design CFM – Used to properly size the dampers based on a maximum FPM air velocity at the register to avoid air noise and still provide enough throw to heat or cool the space. (Typical acceptable FPM 600 to 800)

Max CFM – The maximum amount of air that might move through a damper if it is the only zone open. This assumes the pressure relief is also sized properly (see Pressure Relief below). This will result in more air noise but must be kept at an acceptable level (no more than 900 FPM).

The chart shows the recommended round damper sizes to be uses for Design and Max CFM.

NOTE: These are rough estimates & other duct restriction variables could affect the size damper needed. Consult an HVAC professional if you are unsure.

HOMEOWNER FRESH AIR SWITCH & ECO MODE

CommentGreat use of built-in fresh air features on Ecojay SmartZone-4X zone control system. More details about how to wire one yourself can be found below.

What it does:

FRESH AIR = Equipment FAN (Blower) Runs & Fresh Air Damper Opens

1 = RUNS “x” MIN Per Hour*

2 = RUNS “x” MIN Per Hour* ONLY with EQUIPMENT

3 = ON

4 = OFF

* USE PUSHBUTTONS on SmartZone TO SET “x” MIN RUN TIME PER HOUR FOR FRESH AIR (SEE SmartZone Install Guide)

Today's homes are built with non-porous insulation & air-tight windows & doors to gain the most efficiency possible from the heating & cooling systems. This keeps the outside environment from changing the indoor conditions as much as possible. The down-side of these methods is that virtually NO fresh air (outside air) ever gets into the home. This can mean that the air inside the home can be high in toxins such as VOCs, CO2 & dead skin cells. Of course your air filter (if it's working properly) should remove the larger particulates from the air but some toxins will not be trapped and the only way to remove them is by bringing in outside (fresh) air. The air outside your home is usually cleaner and healthier than inside your home, so, periodically allowing fresh air into your home will make for a much cleaner & healthier living environment. Using the Fresh Air feature of the SmartZone-4X can automatically manage the fresh air intake into your home & with the rotary switch wired as shown below, you can take more control of when and when not to allow fresh air.

A 4 position rotary OFF-ON-ON-ON switch should be used and wired as shown below.

BEST Spring Open Dampers Now Availble

Products1 CommentZoningSupply is now offering the BEST quality Spring-Open damper available. If you have had any experience with SPRING type dampers you already know that they have been known to have a lower reliability than SUPER-DUTY power dampers. However, the Spring dampers that we are offering have been designed with precision and heavy-duty parts.... they are NOT the typical low-cost damper available from other companies. If you are not sure that this is the best spring-damper you have every used, send it back and we will refund your purchase price.

- MADE IN THE USA

- ALL-METAL GEAR MOTOR

- FULLL-SEAL GASKET

- CAPTURED SHAFT (Prevents blade "sticking")

- 5 YEAR Replacement Guarantee

REPLACES:

Honeywell ARD

EWC RSD

ZoneFirst RDS

DuraZone NSPRD

Braeburn 129 ***

AprilAire AVD 66**

& MANY MORE... ANY 24VAC 2-Wire Damper can be replaced with the ECOJAY SmartZone DSUS.

Also available SUPER DUTY POWER DAMPER

What is Zone Control (HVAC Zoning)?

CommentFREE SHIPPING ON ALL ORDERS

CommentStarting this week ZoningSupply.com has started offering free shipping (to the lower 48 states).

Already discounted product prices now make it a no brainer to order zone controls, zone dampers, bypass/makeup dampers, and accessories from ZoningSupply.com.

Super-Duty DAMPERS available at bargain price and now with free shipping!

Replace a Honeywell 4 Zone with SmartZone-4X

SupportCommentUPGRADE your system with an easier & better zoning control. The SmartZone-4X is a drop in replacement for many zone control systems. This is a quick diagram showing where to plug in the wires after disconnecting them from your old HONEYWELL system.

Honeywell HZ432, HZ-432, HZ322, HZ-322, HZ311, HZ-311, HZ221, HZ-221 can all be replaced by the SmartZone-4X in most cases. For more information go to http://www.smartzoning.com